Embellishing print products in an environmentally-sustainable way – we’ll show you how.

Together, naturally

Steinemann DPE digital embellishment systems are known for their highest quality, performance, and cost-effectiveness. We continuously strive to optimize and further develop our products to ensure sustainable and future-oriented print enhancement.

We see ourselves not only as developers but also as partners for the optimal use of our systems. These can be individually tailored to the needs of our customers and thus be used in a resource-conserving manner.

Together with KURZ, we also offer innovative solutions for environmentally friendly, efficient production.

Learn more about how we support our customers in achieving their sustainability goals.

Reduce – conserving resources

The basic principle is to avoid waste and over-consumption.

We will show you how and why – using our print enhancement systems - you can achieve excellent embellishment results while reducing the amount of material used.

Digital Printing - drop by drop, fast, lean & flexible

Unlike conventional decorating, our digital print enhancement systems eliminate the need for additional tools such as embossing dies. Orders are produced on demand and only in the quantities required, eliminating the need for overproduction and inventory. There is virtually no waste in setting up the machines. Customer orders are transmitted directly and can be adjusted at short notice.

Digital Metallization – efficient foil saving function

Our sheet-fed printing systems are equipped with an integrated foil saving function. This enables the most efficient foil use through a complex foil indexing system, even when surfaces are only partially metallized. The saving function can also be used when multiple foils are used.

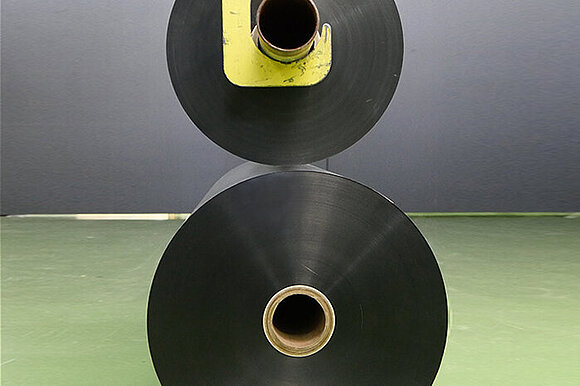

Waste reduction - fewer Microns, more sustainability

With the revolutionary KURZ KPS slim cold transfer products, we have succeeded in significantly reducing the PET carrier material for metallization. This not only helps to minimize plastic waste in your production but also allows each transfer roll to accommodate more running meters of usable decoration. As a result, you get increased usability, more time for applying embellishments, and less time spent on roll changes.

Recycle

Resources used in production should be recycled and remanufactured for reuse whenever possible.

Together with KURZ, we are committed to providing solutions for recycling production materials, consumables and end products.

KURZ Transfer Carrier Recycling

- the KURZ RECOSYS® for PET-Carriers

When finishing surfaces on one of our digital print embellishment systems, no foil is transferred to the substrate. The carrier film used for transfer decoration is released, rolled up and can be collected separately.

In cooperation with KURZ, we now offer a new recycling system for PET carriers called KURZ RECOSYS®.

The PET backing material is collected and processed into a high-quality injection molding material.

Recyclability of decorated end products

For our environmentally conscious customers - and for all consumers of the embellished end products - it is important to know that with Steinemann DPE digital enhancement systems, no plastic parts (PET) or laminates are left on the products.

The disposal properties of paper or cardboard enhanced with the DM-Maxliner 3D do not change. The final product remains fully recyclable and deinkable.

This has been confirmed in tests conducted by the Paper Technology Foundation (PTS) and Propakma GmbH, experts in the recyclability of paper and printed products and packaging.

Find out more about the recyclability of your packaging materials: