Digital varnishing and digital metallization -

universal and unique

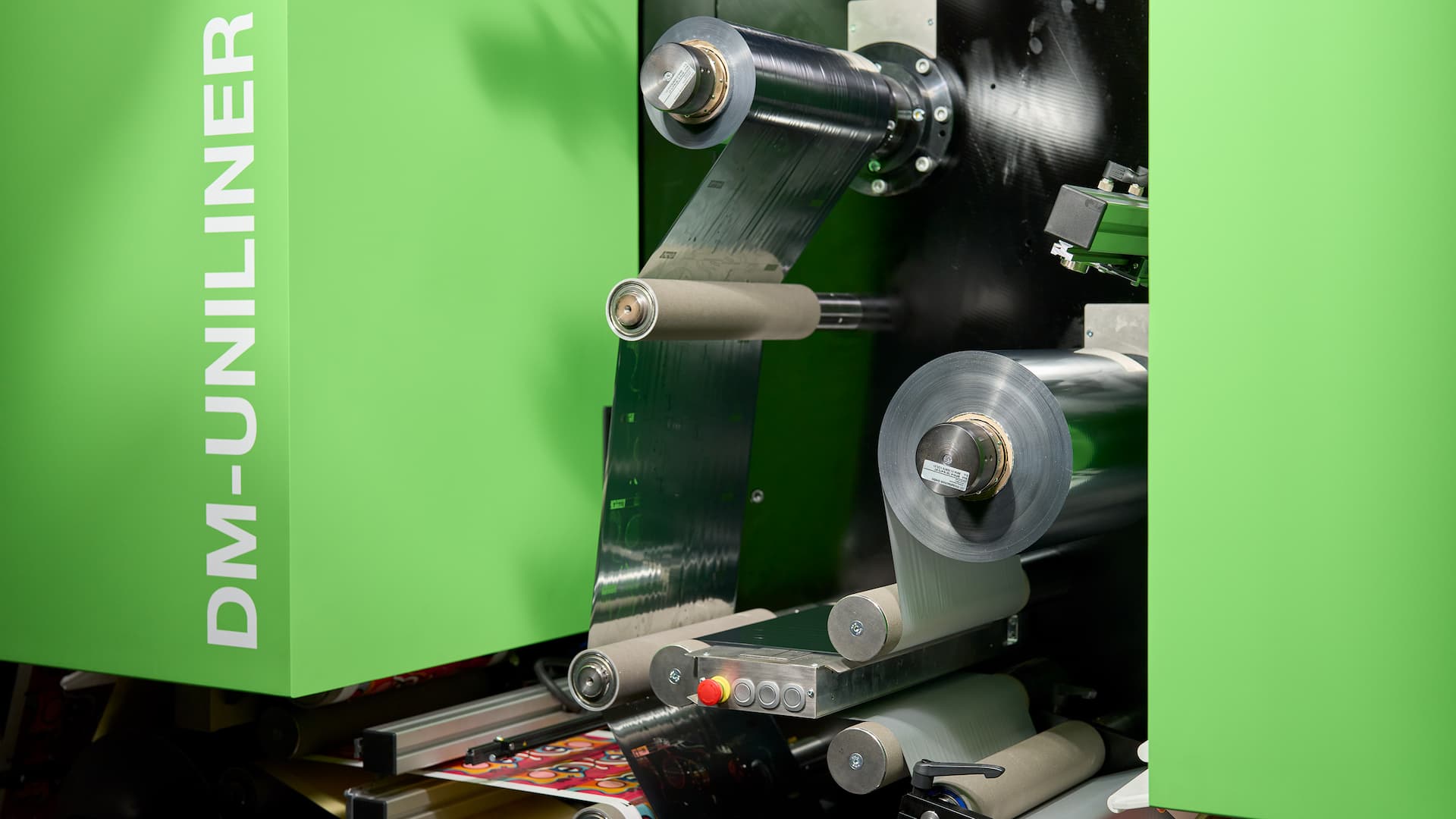

Spot coating, relief varnishing and metallization – all in one operation, applied with digital technology

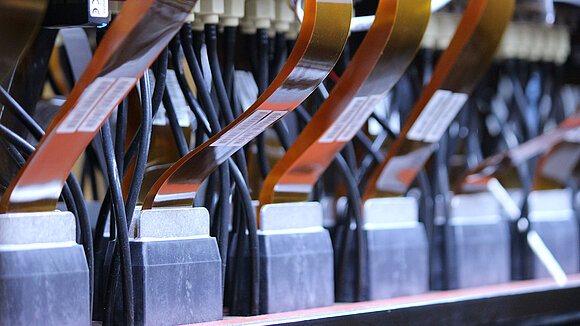

With the DM-Uniliner 3D, design ideas for small to medium-sized product series and special editions can be brought to life in the narrow web. At its core, the DM-Uniliner 3D utilizes Steinemann DPE's industrially proven inkjet technology for varnishing, seamlessly integrated with the cutting-edge KURZ DIGITAL METAL® technology.

High Performance with DM-Uniliner 3D.

Digital embellishment on the Narrow Web. Efficient. Industrial.

With the DM-Uniliner 3D, you can achieve fascinating effects and create exciting designs in a single step through digital metallization and digital varnishing. The machine's "inkjet on substrate" technology offers unparalleled flexibility for the embellishment process, allowing for flat and haptic effects ranging from 4 to 100 μm.

Designs can be metallized either before or after CMYK printing. With a print resolution of 600 dpi, the DM-Uniliner 3D ensures impressive metallization and varnishing quality, resulting in excellent surfaces and intricate structures, suitable for both thin and thick layers. Moreover, the digital metallization can be over-varnished and protected using digital UV spot varnish.

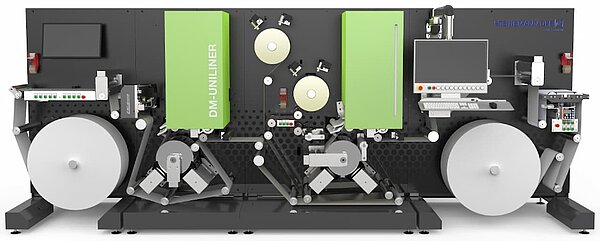

Modular based on investment readiness

The option of scalable components makes it possible to enter into digital embellishment with a lower initial investment, with the ability to expand the machine’s capabilities as the workload grows. Alternatively, you can choose the fully equipped configuration right from the start.

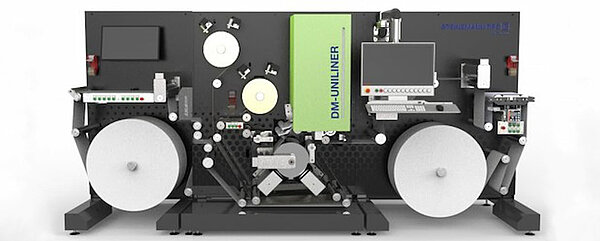

In the basic configuration, the machine is equipped with only one printing tower. This allows either digital UV varnishing or digital metallization to be applied in a single pass. If both embellishments are required for the same job, two passes are required.

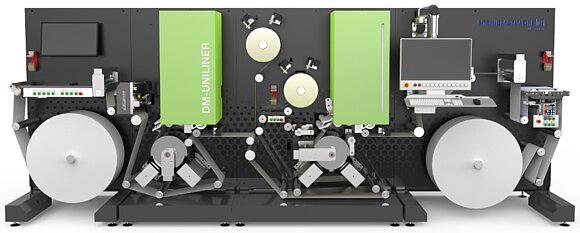

The twin configuration has two printing towers. This means that digital varnishing and digital metallization can be applied in one pass. The significant advantage is that if the job requires both finishes, it only needs to go through once.

Assets of the DM-Uniliner 3D

Top performance in digital varnishing and brilliant DIGITAL METAL® effects in a new dimension:

Video

Witness the DM-Uniliner 3D in action and experience digital embellishment for narrow web at its best.

Technical data

| Substrate | |||

|---|---|---|---|

| Web width | min. 100 - max. 340 mm | ||

| Core diameter (3''): | 75 mm | ||

| Roll diameter unwind and rewind: | max. 800 mm | ||

| Print system | |||

| Inkjet system: | Drop on Demand, Single Pass | ||

| Native resolution: | 600 dpi | ||

| Varnish lay down ²)³): | 4 - 50 g/m² | ||

| Print speed ¹): | 10 - 100 m/min | ||

| Register accuracy: | +/- 0.15 mm | ||

| Image format: | |||

| Data transfer: | USB, Hotfolder | ||

| DM-Unit for DIGITAL METAL® | |||

| Web width: | min. 50, max. 330 mm | ||

| Number of webs on the shaft: | bis max. 6 | ||

| Core diameter (3''): | 75 mm | ||

| Roll diameter: | max. 300 mm | ||

| Stamping speed (depending on stamping size area): | 15 - 50 m/min | ||

| Dimension / Weight | |||

| Dimension (LxHxW): | 4,000 (5,000 º) x 2,000 x 2,600 mm | ||

| Module net weight: | ca. 5,250 (6,750 º) kg | ||

1) = depending on varnish lay down and substrate type

2) = Depending on working speed

3) = Depending on varnish type and surface tension

0) = Twin configuration

All technical data represent approximation values. Steinemann DPE reserves the right to make mechanical and design modifications.

Narrow web

Labels not only inform, they convince. Digital finishing can make the difference - even for short and medium run lengths.

Steinemann DPE single source

system solutions

Steinemann DPE, together with Leonhard KURZ, offers outstanding, high-quality system solutions for industrial, digital metallization and digital varnishing.

From the machine to the transfer metallization to the ink, we offer you all components from a single source – perfectly matched to each other.

Consumables

To achieve the best possible results, you need to use the right consumables that are optimized for your machine and your needs.

We will be happy to guide you.

Spares

Wear and tear is inevitable when machines are used intensively. We provide replacements.

Sustainability

Sustainable production with digital print embellishment?

Learn how sustainable print enhancement is possible with Steinemann DPE systems.

Would you like to learn more?

Do you have any questions, would you like more information, samples or brochures?

Please contact us.

We will be happy to assist you.